Colex Cut Center 8

Colex Cut Center 8

- Supports industrial automatized workflows

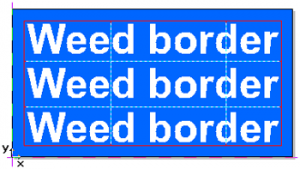

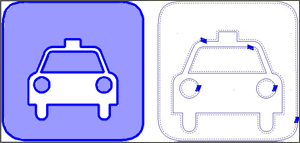

- Minimizes share of rejects because of

– optical recognition system

– print divergency compensation - High-End lens/OS Camera combination allows

– Usage of miscellaneous video marks (also colored

ones)

– High speed mark recognition

- Vectorization – automatic raster to vector conversion

- Text editor with single line font support

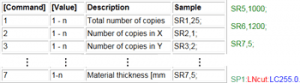

- Serialization – creation of non-identical multi-copies with

- Bitmap tools

- Drawing tools like polygon, square, line, curve, gradient fills

- Node editing tools

- Object Manager

- Clipart Manager

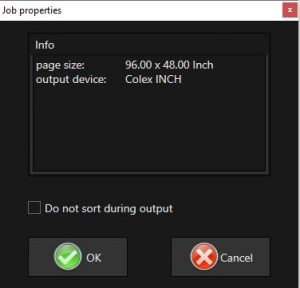

- Job Calculation and Job Info

- Option for OS Front-End and OS Production

- Users, who want to edit job data before output

- Job preparation on design clients without direct output option

- Note: Only soft code (no dongle)

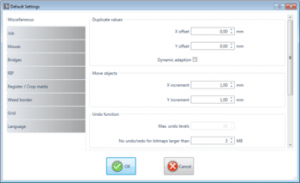

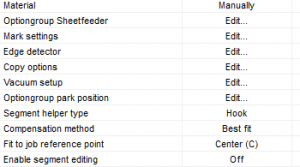

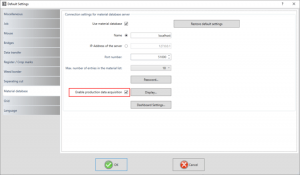

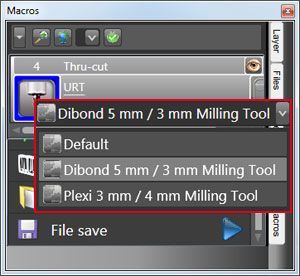

- Saving and retrieving the correct method when editing a particular material

- Each material can be assigned to one or more – also

different – devices - All parameters are set to the values

that are required for a perfect material handling - New materials can be added anytime

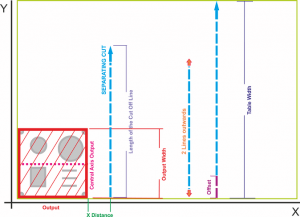

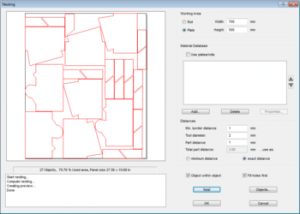

- A production profile that controls the entire

production process

- Working with a material database is faster and more reliable than rule of thumb method

- Minimization of rejects while maintaining process quality

- High, consistent product quality

- Output file contains inherently all technology data for a frictionless production

- Access to the database locally on the client computer or alternatively to a production computer / server via LAN

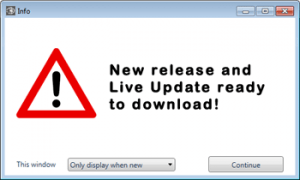

- Industry 4.0 Production

- Macro Player reduces the operation to the essentials

- Automatic file search with job import

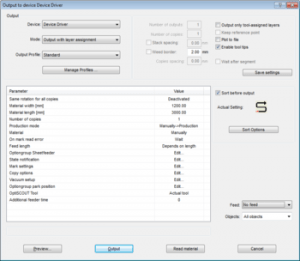

- Image processing profile contains all relevant data for image processing

- Output profile inherently contains all technology data for a smooth production

- Access to the appropriate job file is done via QR code

- Start by mouse click

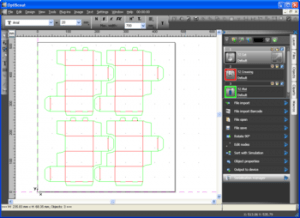

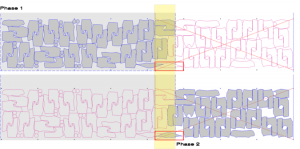

- Individualized serial production

- Flatbed machines with camera (cutter, milling machine, laser)

Usability

PrePress/Design

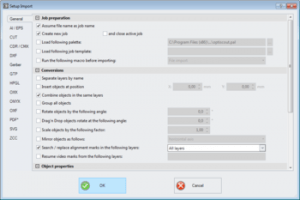

Job Preparation

*.PDF, *.AI, *.EPS, *.WMF, *.EMF, *.DXF, *.IK, *.GTP, *.JTP, *.JOB, *.HPGL, *.CMX, *.GBR, *.ISO (Gerber), *.SVG

*.PCX, *.TIF, *.BMP, *.GIF, *.JPG, *.CMP

*.DMPL Summa DMPL files with OPOS markers

These filters are necessary for data exchange with other Finishing Systems:

*.CUT I-Cut Vision (up to Version 6)

*.ZCC Zünd Cut Center

*.ACM Esko

*.OXF Colex Cut Center 8

Special features: When importing, special operations such as Mirroring and Insert at position can be set.

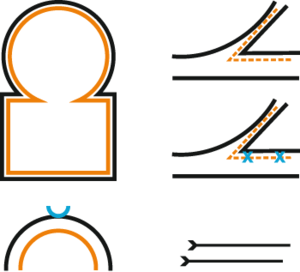

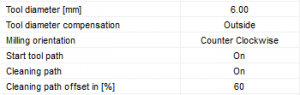

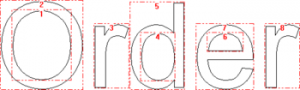

Finishing

Production Data Acquisition (PDA)

Colex Cut Center 8 RIP Software Compatibility

| RIP Manufacturer | QR Code Print | DB Layer Names | Material Database Access | File Format |

|---|---|---|---|---|

| Ergosoft | Yes | Yes | Yes | OXF |

| Colorgate | Yes | Yes | No | OXF |

| SAi | No | Yes | Yes | OXF |

| Onyx | Yes | Yes | Yes | Onyx XML |

| Caldera | Yes | Yes | Yes | OXF |

| Wasatch | No | Yes | No | OXF |

| Asanti | Yes | Yes | No | |

| Cadlink | No | Yes | No | OXF |

| EFI Fiery | No | Yes | Yes | OXF |

| Prepare-It | Yes | Yes | No | |

| PrintFactory | Yes | Yes | Yes | OXF |

| Colorburst | No | No | No | N/A |

| Aarden | No | No | No | |

| Engview | No | No | No | |

| Caldera | Yes | Yes | No | ZCC / PDF |